Automotive Components Manufacturing

Products & Services

Automation Solution Provider

Engineering Services

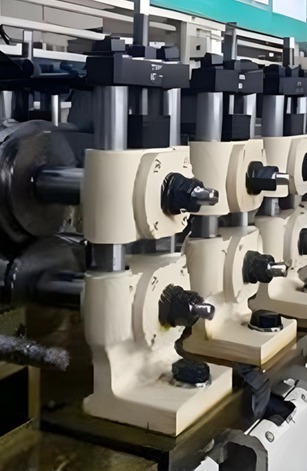

ROLL FORMING DIES (DOOR SASH , INNER SASH)

DOOR MODULE ROLL FORMING DIES (DOOR SASH , INNER SASH)

(a) DESIGN AND PRECISION

Door sash roll forming dies are designed with precision to create the exact shape and size required for door sashes, ensuring consistent quality and performance. We provides comprehensive solution form flower design concept. tool design, FEA simulation, fabrication & trial for door sash manufacturing.

(b) MATERIAL AND DURABILITY

Door sash roll forming dies are made of high-quality steel, engineered to withstand the high pressures and temperatures involved in the roll forming process, ensuring long-lasting durability and reliability. The design can be from 30 to 40+4 steps depended on complexity of the door sash profile.

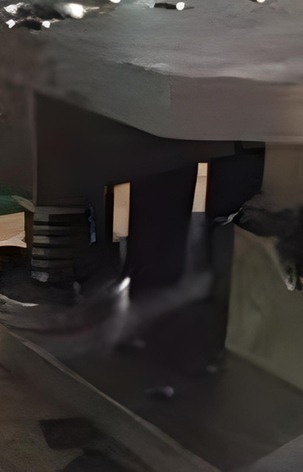

STRETCH BENDING DIES

DOOR MODULE STRETCH BENDING DIES

Sealing system stretch bending dies are precision metalworking equipment that are used to create the curved shape required for various sealing system such as Weatherstrip or Roof Drip Moulding. These dies must be engineered to produce consistent and accurate results, ensuring that the part is of high quality and fits perfectly in the frame.

SEALING SYSTEM ROLL FORMING DIE

DOOR MODULE ROLL FORMING DIES (DOOR SASH , INNER SASH)

(a) DESIGN AND PRECISION

Door sash roll forming dies are designed with precision to create the exact shape and size required for door sashes, ensuring consistent quality and performance. We provides comprehensive solution form flower design concept. tool design, FEA simulation, fabrication & trial for door sash manufacturing.

(b) MATERIAL AND DURABILITY

Door sash roll forming dies are made of high-quality steel, engineered to withstand the high pressures and temperatures involved in the roll forming process, ensuring long-lasting durability and reliability. The design can be from 30 to 40+4 steps depended on complexity of the door sash profile.

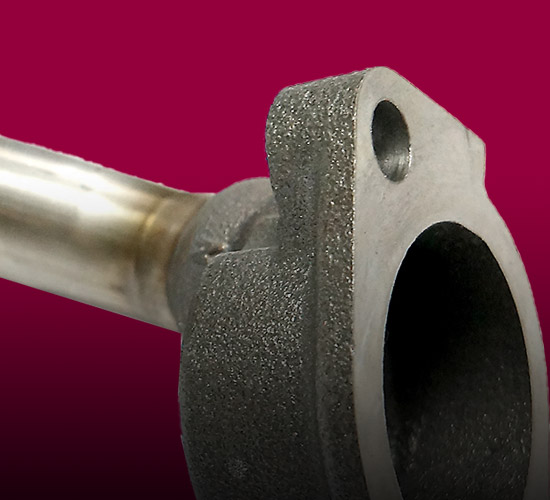

ROLL FORMING EXTRUSION & FLOCKING TOOL

ROLL FORMING EXTRUSION & FLOCKING TOOL

Roll forming extrusion dies are used to create complex cross-sections for sealing products, which allows for the production of intricate shapes and contours. Our design can cater for various combination of co-extruded materials. Metal parts can be galvanized or non-galvanized steel, various type of stainless steel, aluminium or annealed flat metal insert.

Extruded materials can be PVC or PP/TPO applied using multiple numbers of extruders based on profiles complexities.

Flocking will be applied after extrusion process either by applying flocking tape or electrostatic flocking application method .

DOOR MODULE STRETCH BENDING DIES

SEALING SYSTEM ROLL FORMING DIE

Sealing System roll forming dies are designed with precision to create the exact shape and size required for various type of sealing system, ensuring consistent quality and performance. IKTC provides comprehensive solution form flower design concept. tool design, FEA simulation, fabrication & trial for sealing system manufacturing such as Roof Moulding, Beltline and Windshield.

Roll formed material can be co-extruded with PVC or PP/TPO or coated with glossy finish.

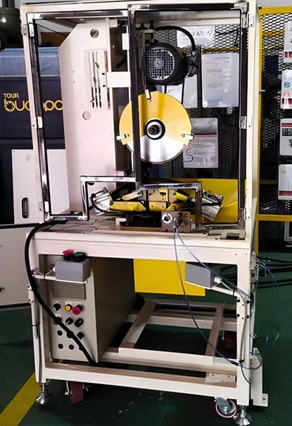

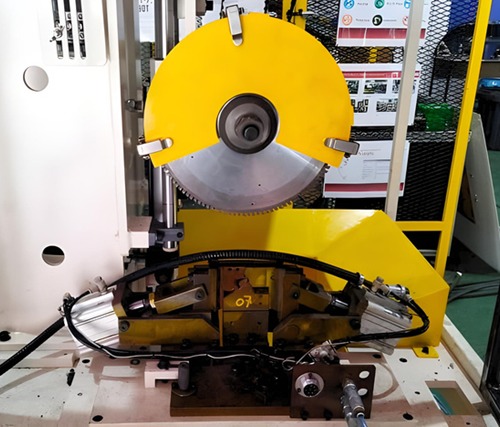

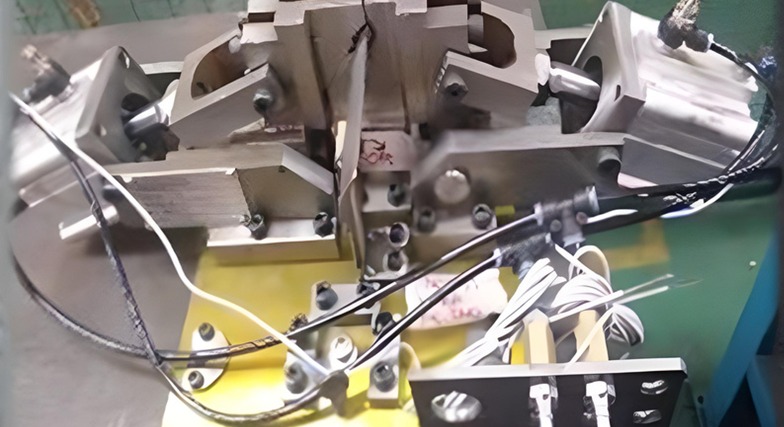

METAL SAW CUTTING JIGS

METAL SAW CUTTING JIGS

Several factors affect metal saw cutting, including the type of saw blade, the speed of the saw blade, the feed rate, and the most important thing is the quality of cutting jig. Understanding these factors is essential for achieving consistent and accurate cuts.

Our metal saw cutting jig ensure accurate angle cut and secure clamping to ensure safety operation. The jigs also equipped with automatic clamping, foolproof mechanism and safety sensors.

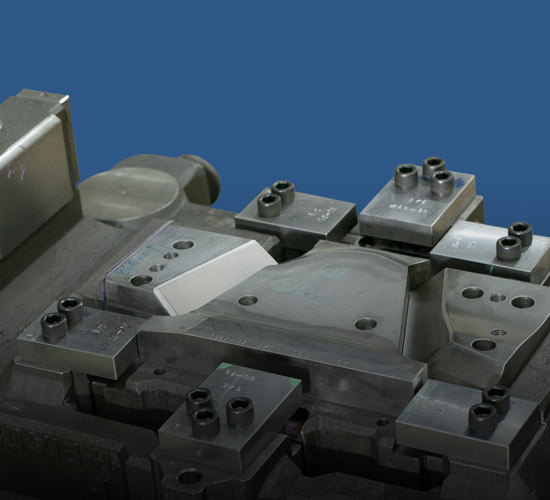

OVERVIEW OF PRESS DIE

OVERVIEW OF PRESS DIE

Press Dies

Press dies are specialized tools used in manufacturing that are designed to cut and shape metal into specific forms. They are used across a wide range of manufacturing industries to create a variety of shapes and sizes.

Types of Press Dies

There are several types of press dies, including blanking dies, piercing dies, trimming dies, and forming dies. Each type is used for a specific manufacturing process and creates a specific shape or form.

SEALING SYSTEM ASSEMBLY JIGS

SEALING SYSTEM ASSEMBLY JIGS

Assembly jigs are used to hold components in place during sealing system manufacturing processes. Various type of assembly jigs designed and fabricated to ensure efficient assembly of sealing system like clip insertion, end cap insertion, heat jointing, foolproof check, and others.

INSPECTION JIGS AND CHECKING FIXTURES

INSPECTION JIGS AND CHECKING FIXTURES

Our Inspection Jigs and Checking Fixtures are designed with precision and meticulous attention to detail to guarantee the final product's accuracy and consistency. Our development processes involve comprehensive interaction and collaboration with customers, from design concept to assembly design to detailed design.

Our CAD/CAM facilities, combined with our table size capabilities and mobile CMMs, ensure that the final result aligns perfectly with approved design data.

Chat

With Us.

Reach us out, give us a call or just drop an email.

Our friendly team will assist you with your enquiries and questions.